Tool Automation

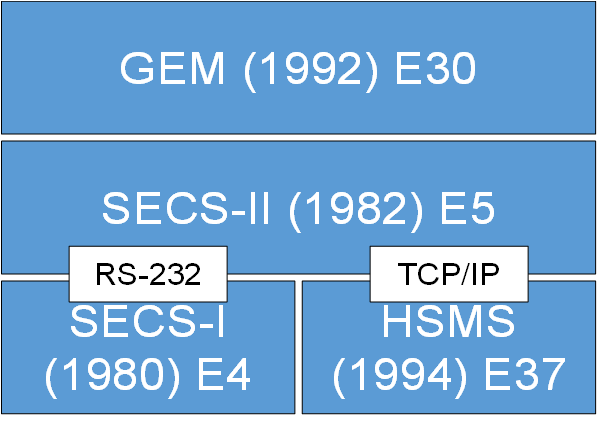

Data Acquisition Solution(SECS/GEM & Non-SECS)

Support SECS / GEM communication for the machine connection, retrieve the required information(SV) of SECS message and apply it.

SECS Standards

Scope of Application

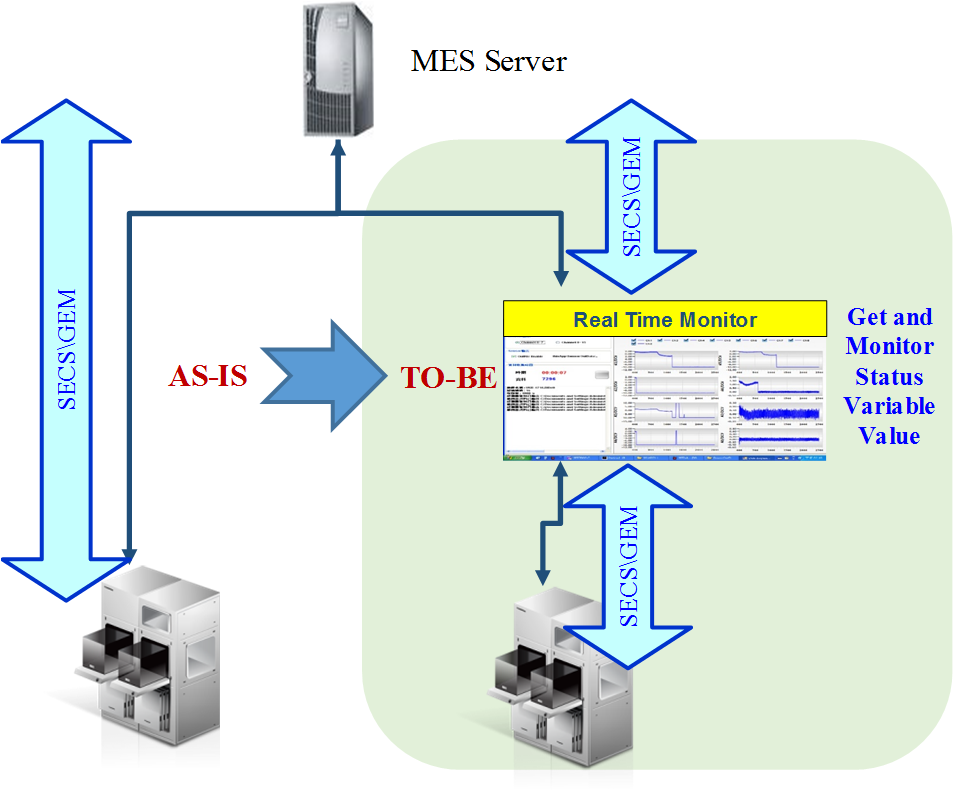

SECS/GEM Automation : Machine has SECS / GEM communication capabilities. This Solution can customize program to communicate with MES then achieve mutual communication.

SECS/GEM Automation Architecture

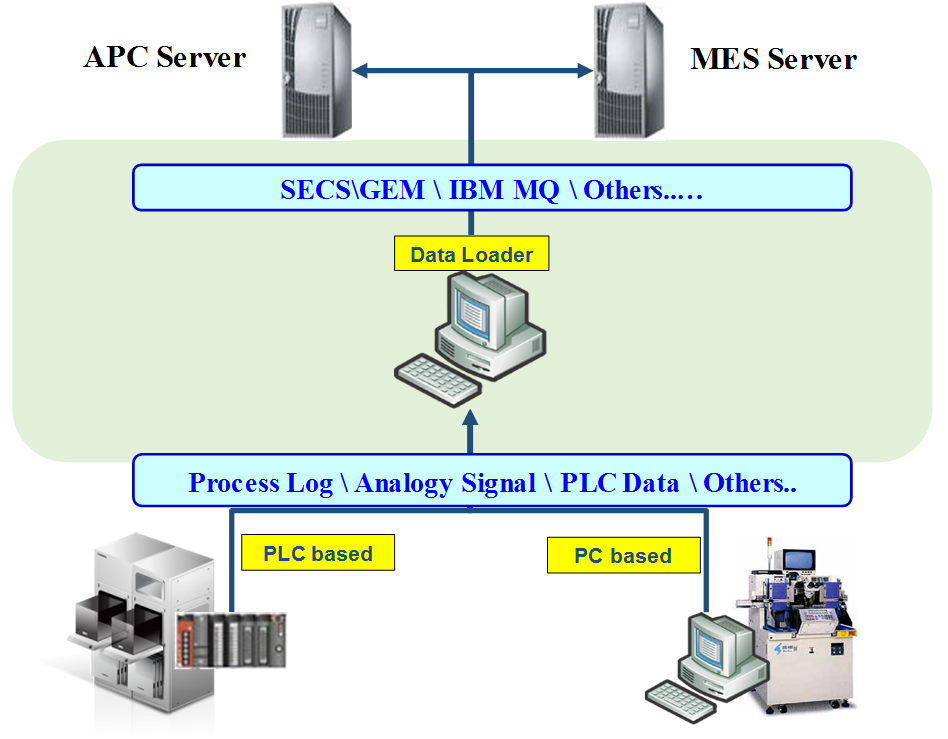

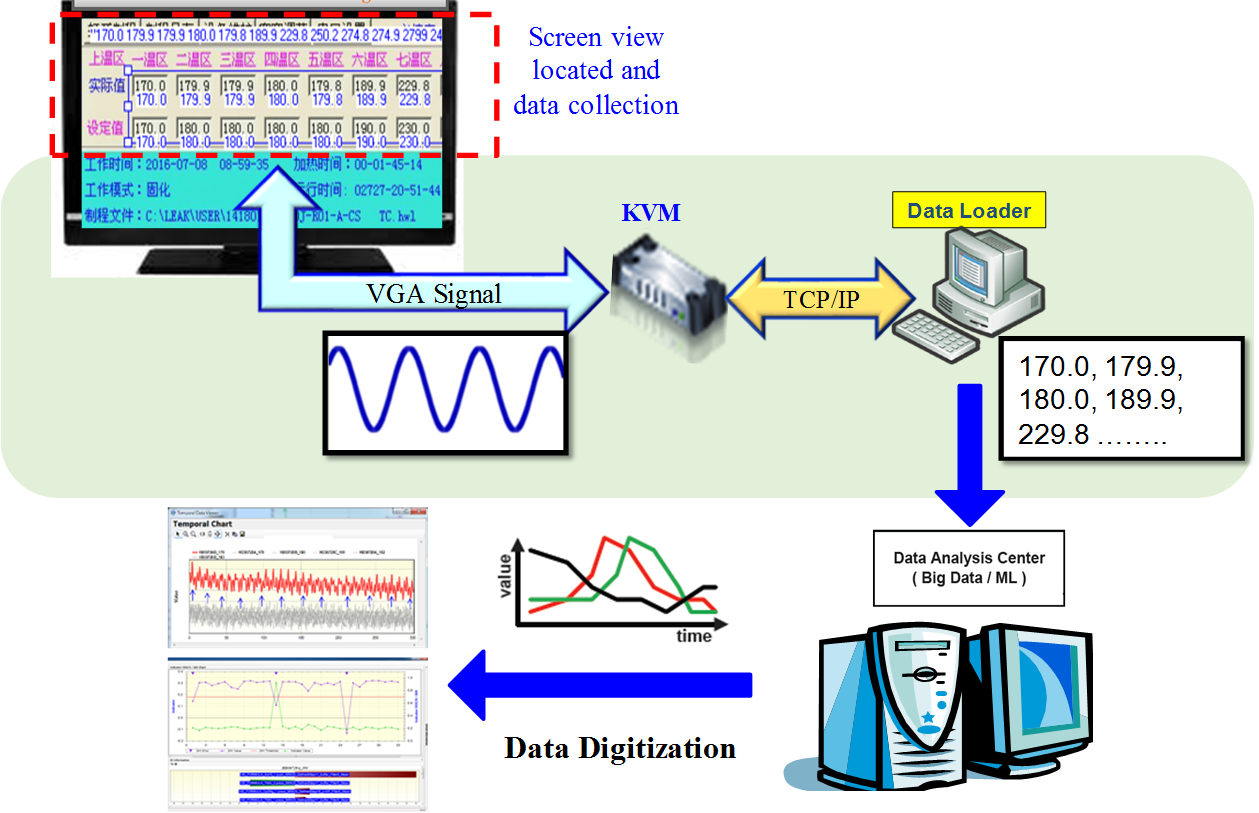

Non-SECS DAQ Solution 1 : Data Loader

Data Loader : Machine has log or database of the manufacturing process, and records all the process information in detail. We can add "Data Loader" to convert machine signal and data into communication format such as SECS\GEM, IBM MQ...,etc.。

VGA Screen Signal Capture and Digital Conversion : Machine has VGA signal output and provide analog signal is suit for the solution which can locate the area on the screen where user want to capture and output the value digitally.

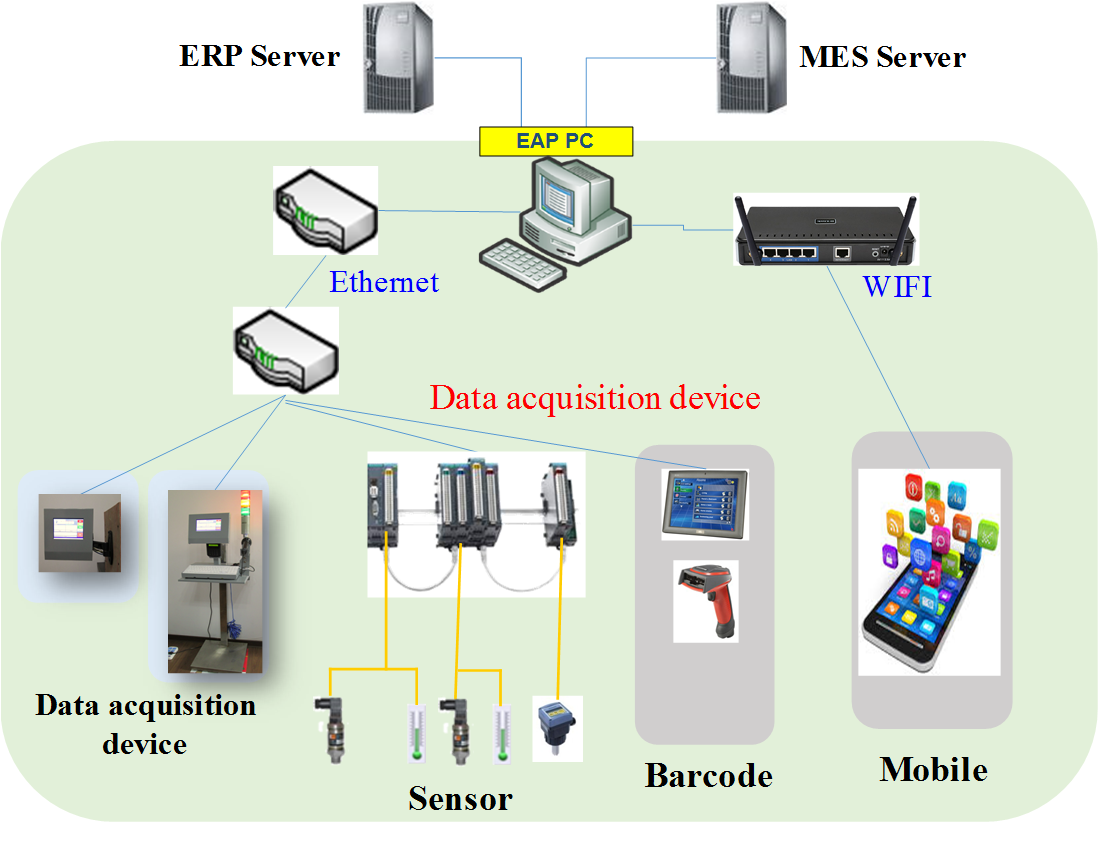

Non-SECS DAQ Solution 2 : DAQ Device + EAP PC

If there isn't any external data communication of machine, we can only upgrade the machine, install sensor or customize the data acquisition devices to communicate with EAP PC through customized communication protocol. The data acquisition process are customized all to achieve mutual communication.

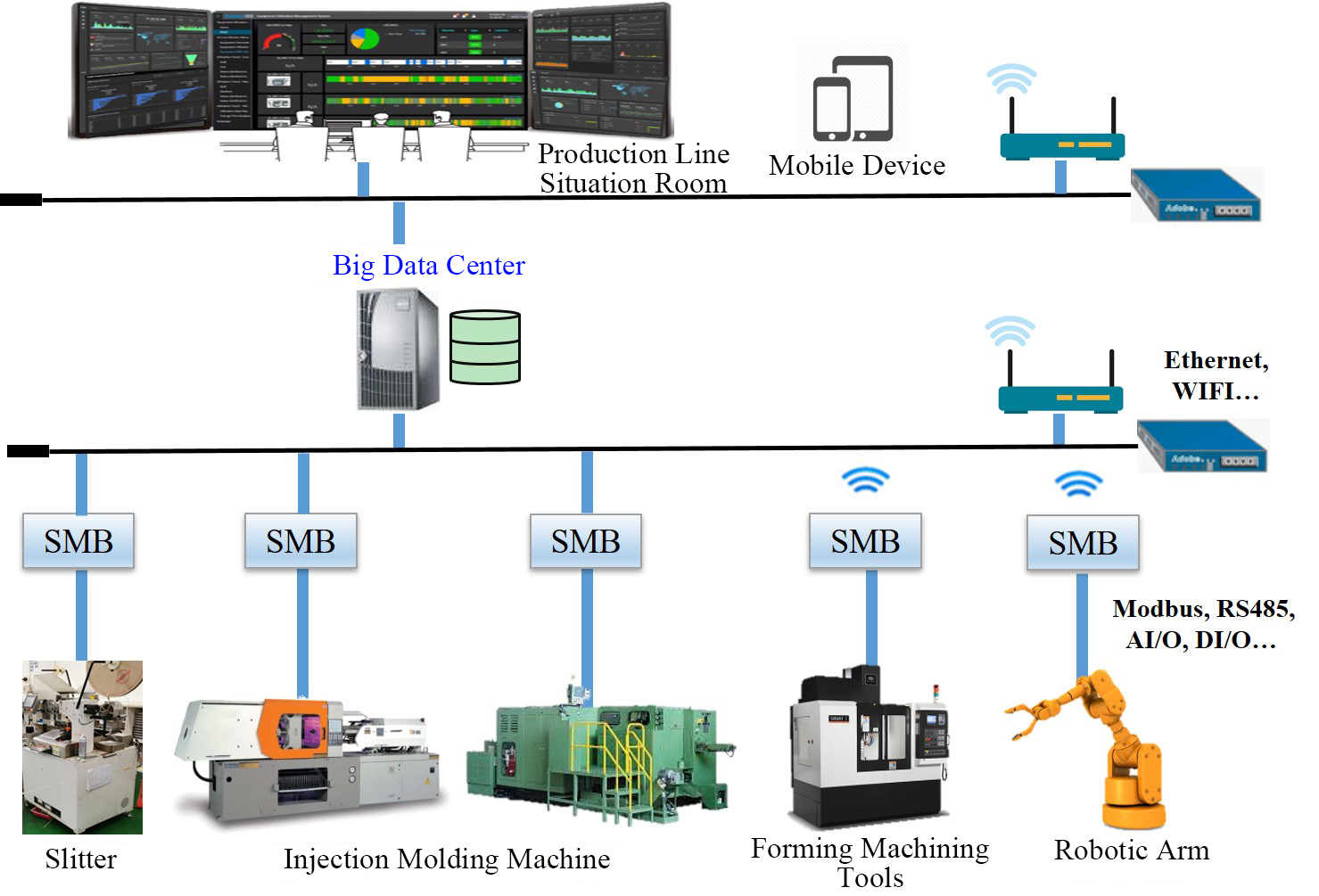

Smart Box

Traditional industries' capability of digitalization is too insufficient to meet the era of smart manufacturing. Take fastener industry as an example, data of prodction line is mostly recorded in paper, which relies on manual operations and is difficult to improve the capability of intelligent machinery.

By adding sensors and the development of Smart Box, user can aquire all data from tool and use it for further analysis.

Smart Box Common Module Function

Tool Connection Setting Management: For connected tool parameter setting and online tool management, such as adding, deleting, and modifying.

Data Aquisition and Storage Management: Smart Box is a software that retrieves data from process tool and provides the functions of processing, storing and translating the data transmitted from process tool.

Equipment Utilization Management: Smart Box is able to display utilization rate by the aquisition of tool's on-off status and time information.

Completion Estimation: Smart Box is able to capture tool completion status and operation time, which enables to display the ratio of process completion.

Tool Operation History: Smart Box is able to record and store status and time information of tool and display in graphic. In addition to utilization rate and completion ratio, Smart Box has more than 2 distinguishable tool status information records (e.g. failure type, tool operating parameters, programs, tool stand-by type or work in progress information...etc.).

Active Notification of Tool Abnormal: When a major alarm (such as a failure or unexpected shutdown) occurs, alarm message will be passed to relevant staff through Smart Box and which provides at least one handheld device notification (such as mobile text message, handheld device instant messaging, etc.).

Order Completion Time Estimation: Smart Box aquires the completion time of a single unit with same order under specific tool (or system) or calculates the average completion time based on historical data and is able to forecast expected completion time of all production.

International Compatible Communication Standard: Smart Box uses at least one internationally compatible communication standard protocol.

System Architecture