Advanced Manufacturing Cloud of Things (AMCoT)

Brief Introduction

Imdustr 4.0 + AVM = Imdustr4.1--Automatic Virtual Metrology System

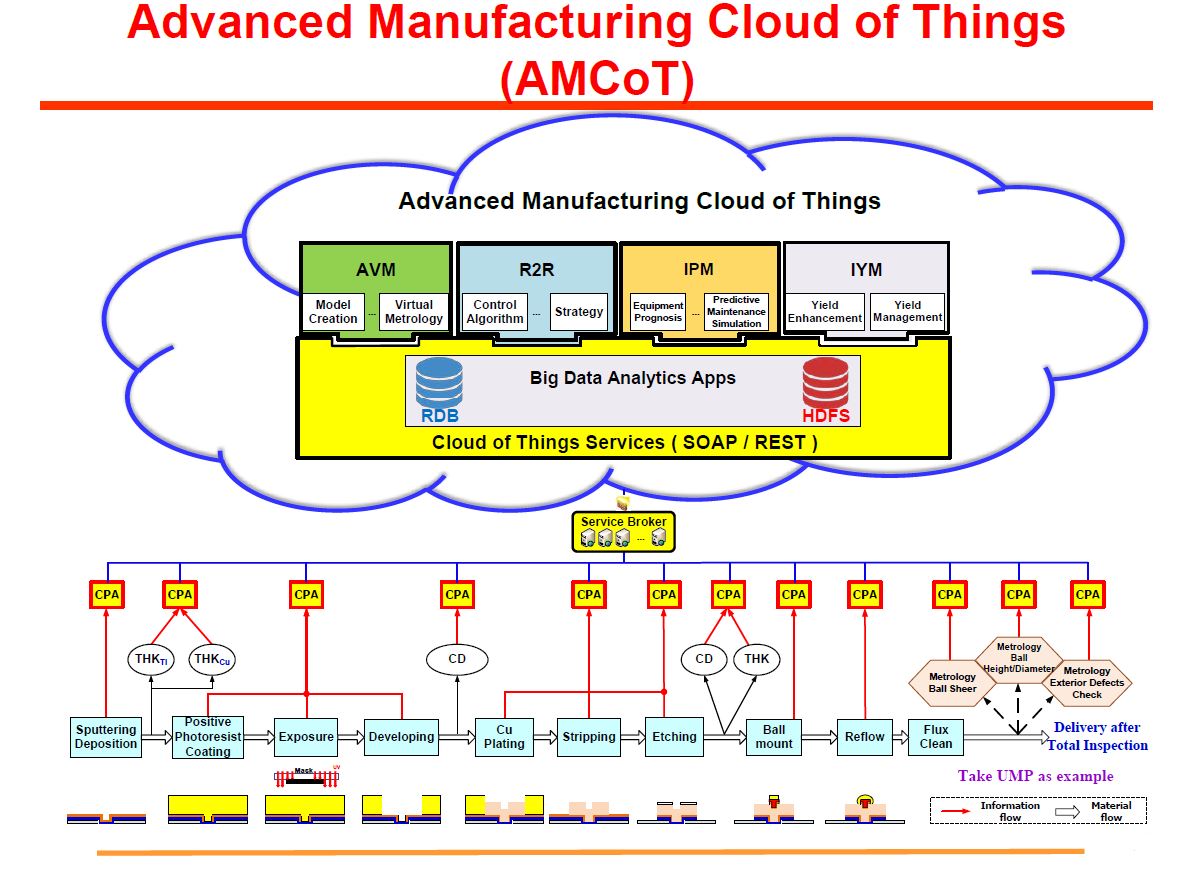

To improve the automation and intellectualization of the manufacturing systems so as to enhance the product yield and reduce production cost, our team utilizes Internet of Things (IoT), Cloud Computing (CC), Cyber-Physical System (CPS), Big Data Analytics (BDA) and AVM to develop the Advanced Manufacturing Cloud of Things (AMCoT).

Strategies for Increasing Yield in Ramp-up and Mass-Production Phases

In Ramp-up Phase

(1) Yield Enhancement Service (YES): Find out the root causes among numerous yield-affecting parameters, put them under control and exclude them in a timely manner to increase the yield in ramp-up phase.

(2) Baseline Predictive Maintenance (BPM) & Tool Matching (TM): Establish the tool failure cause relations and create BPM model to infer the timing of the coming tool failure in order to decrease tool abnormality chances and increase yield rate. Tool Matching is also performed in this phase.

In Mass-Production Phase

(1) AVMand Intelligent Predictive Maintenance (IPM): Convert the offline sampling inspection with metrology delay into online and real-time total inspection to achieve the goal of defect early warning; and obtain the best tool maintenance timing to reduce maintenance cost.

(2) Run to Run (R2R): Integrate R2R with AVM to enhance the stability of production process (Cpk).

(3) Yield Management System (YMS): Quickly find out the root causes of a yield loss and deal with them.

In terms of technological benefits of this project, by the total-inspection capability of the CPAVM service, abnormal products can be timely detected and thus excluded during the production.

This project can leverage academic research capacity to help domestic manufacturing industries go toward the realm of zero-defect products of Industry 4.1 which is defined as Industry 4.0 plus AVM by our team.

Benefits:Enhance the Productivity & achieve zero-defect in production

By using the BDA-based YE and YM services, the key stage influencing yield in the production line can be found.

By using the cause-effect-relationships (CERs) established by the CPAVM and CPEP/CPPMS services, the key factors causing yield decline can be discovered and suggestions about conducting predictive maintenance on equipment can be provided

Continuous improvement can make the products in manufacturing near zero defects.

-

Applications

- Semiconductor

- Solar-cell

- Machine-tool

- Other high-tech industries and traditional industries