Automatic Virtual Metrology System (AVM)

Brief Introduction

Automatic Virtual Metrology System(AVM) uses data from production tool to predict product quality when products are unmeasurable. Change random inspection with delayed feature into inspect all in real time.

The AI Algorithm of AVM Prediction Model is based on BPNN (Backpropagation Neural Network) and PLS (Partial Least Square) and which is for Model to process Self-Learning and adapte to different prodct line after fan out. In addition, the AVM system provides reliance index and data quality index to ensure the quality of process data and measurement data and which is to ensure the quality of the prediction and meets the purpose of online predict accuracy.

Features

Suitable for on-site platform AI solutions, allowing users to quickly fan out prediction models to factories and production tools

By back-end and automation of AI technology, even User doesn't have AI related knowledge but can still finish complex procedure as causal work with SOP in 20~30 minutes.

Solutions for different process types (such as Single Chamber, Multiple Chamber, Line, Roll-to-Roll, Continuous or Front and Rear Process Integration)

AVM has patented technology to solve the difficulties of modeling that the sampling rate of inspection is dropping rapidly.

Meet the requirements of VM system’s high precision and reliability.

The prediction model process Auto Refresh during the events such as machine cleaning, tuning and time-varying.

AVM is applicable in situation of small-volume, large-variety production and tools with multiple Chambers by automatic fan out mechanism.

AVM can precisely predict the average and the quality of each point (Uniformity).

R2020a Update

| Function | Description | Benefits for USER |

|---|---|---|

| KPI Web -Reference | Turn VM Client into Web page | User Friendly。 |

| VM Hint | AVM Hint is a notice message when the condition of prediction and process/measurement tool is unstable,which notifies user to increase the sampling rate or pieces to be measured for stabilizing prediction. | Assist user to analyze production fluency and stability in factory, and to reduce the cost caused by unstable prediction. |

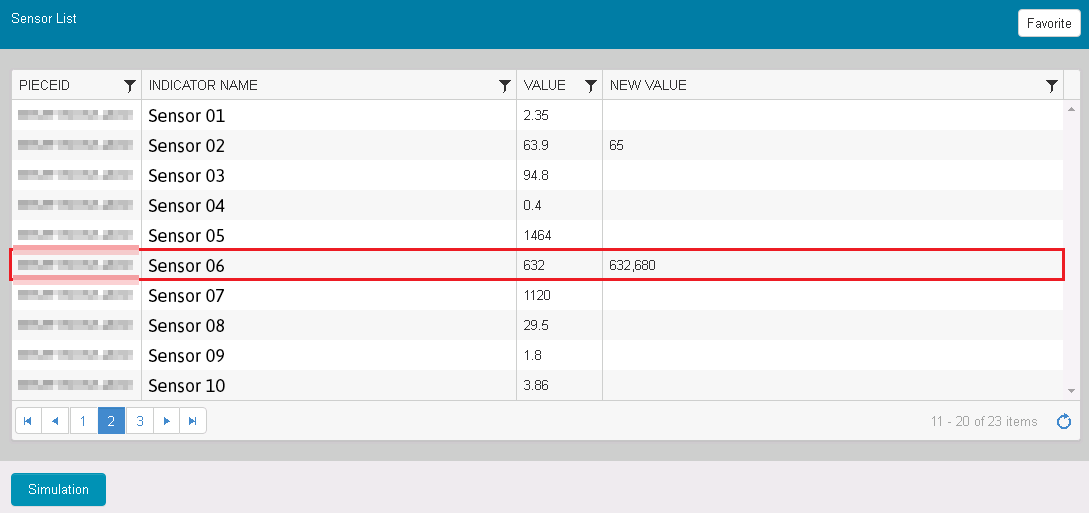

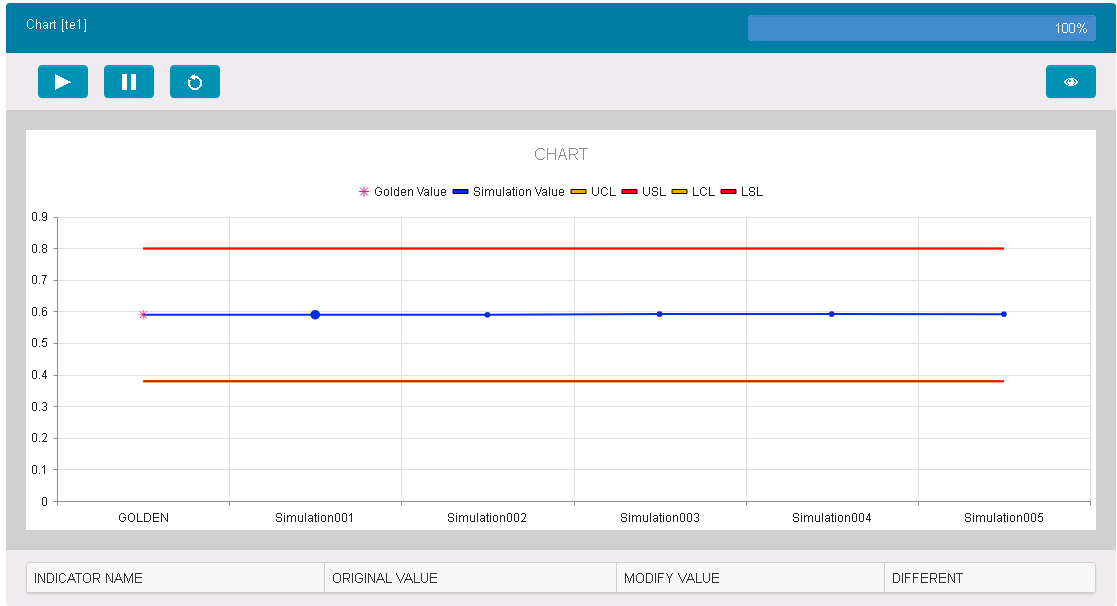

| Pilot Run Simulation | By using each product's prediction model and the process/measurement data of the lastest production piece under the model as the benchmark, user can simulate the measurement values of each sensor combinations. | Reduce time of Pilot Run, speed up production process and increase activation. |

|

||

| Prediction Priority Adjustment Mechanism | User can adjust the prediction sequence by external control system, the mechanism also provides external interfaces for AVM system operations to fulfill the needs of in-factory shipments. When the function is executed, IT department in the factory can predict the specific ID by AVM system. | Fulfill user's need of immediate order insertion to ensure timely delivery. |

AI Functions

| Function< | Description | Benefits for USER | Offset Complement | User system software to solve inevitable hardware differences(Offset). Regard the differences between the machines as a indicator for prediction and insert to AVM model, which eliminates the impact of tool difference for predition model. | In the prediction system, for the time-varying condition of the machine difference, it is remedy for the prediction system in an automated manner,which reducing the burden on maintaining the stability and the machine balance. |

|---|---|---|

| Models Automatic Fan Out |

While new product which has same spec as old product is launched, User doesn’t need to build new models but only to directly fan out existing models for monitoring and predicting. | Quickly fan out models when new products are launched. |

| 0 Run Building Models | When the new product is launched, the model can be automatically fan out and predict after the first run of new product. | |

| ISD(Intelligent Sampling Decision) Mechanism | When the system identifies the process or the measurement tool is unstable, the extra measurement decision will be made automatically. | Each measurement is effective. |

| Weight of Parameter Presented | Shows the weights of the prediction model parameters and charts of Response surface in the web interface. | User can understand what parameters affect product quality and the level of these parameters impact. |

Benefits: Improve Uniformity and Enhance the Gross Profit

FS-Tech's AVM is applicable to all industries and process. AVM platform can extensively gain customer feedback and quickly improve customer experience.

100% Inspection and greatly Reduce the Sampling Rate of normal products (≧ 30% )

Reduce Cycle Time (≧ 3% )

Decline the Frequency of Monitoring Tool (≧ 50% )

Reduce the capital expense of measurement tool (≧ 30% ) & Space saving

Reduce Direct Labor of Measurement Department (≧ 30% )

Market Achievement & Experience

FS-Tech has a lot of successful experience in industries such as panels, semiconductors, solar energy, chemical industry and machine tools (more than 170 sets of AVM have been sold).

The main processes of panel industry -- Array/CF/Cell process have been integrated.

Compared with VM competitors in Europe, America, Korea and China, FS-Tech has achieved an excellent results in all fields.

-

Applications

- Metal Micromachining

- Automobile Industry: Rim Manufacturing

- Panel Industry:Array、CF、Cell

- Semiconductor: Wafer manufacturing, IC manufacturing, Probe and Packaging

- Molding Machine Industry

- Aerospace Industry