eRunCard

Brief Introduction

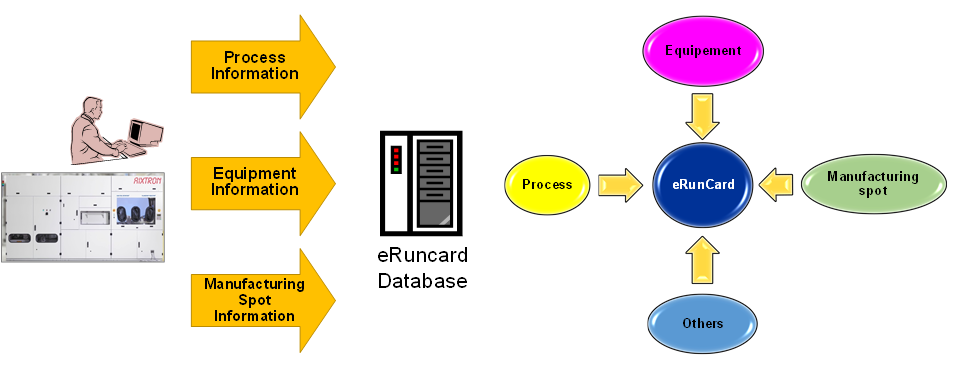

Start from the perspective of products, integrate and electronize related processes that affect the products and related production site information of manufacturing and tools, then integrate them with eProcessKey and iEDA for further improvement.

Features and Functions

Automatically retrieve equipment information(through SECS/GEMS or Data Parser), and integrate with machine, equipment and manufacturing site to enhance productivity for easy tracking and analysis.

Provide simple real time monitor function

Calculate the use of parts and raw materials, and use calendar view show forecast replacement date(PMS) of raw materials and parts.

Export eRC data according to requirements regularly to facilitate production management.

Benefits

Reduce human resource waste and avoid manual transcribing errors

Display process information and tool conditions immediately to avoid the continuous production of abnormal products

Real-time management of tool parts, constant, and source to avoid misuse